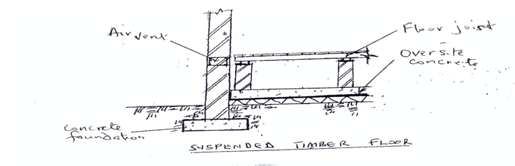

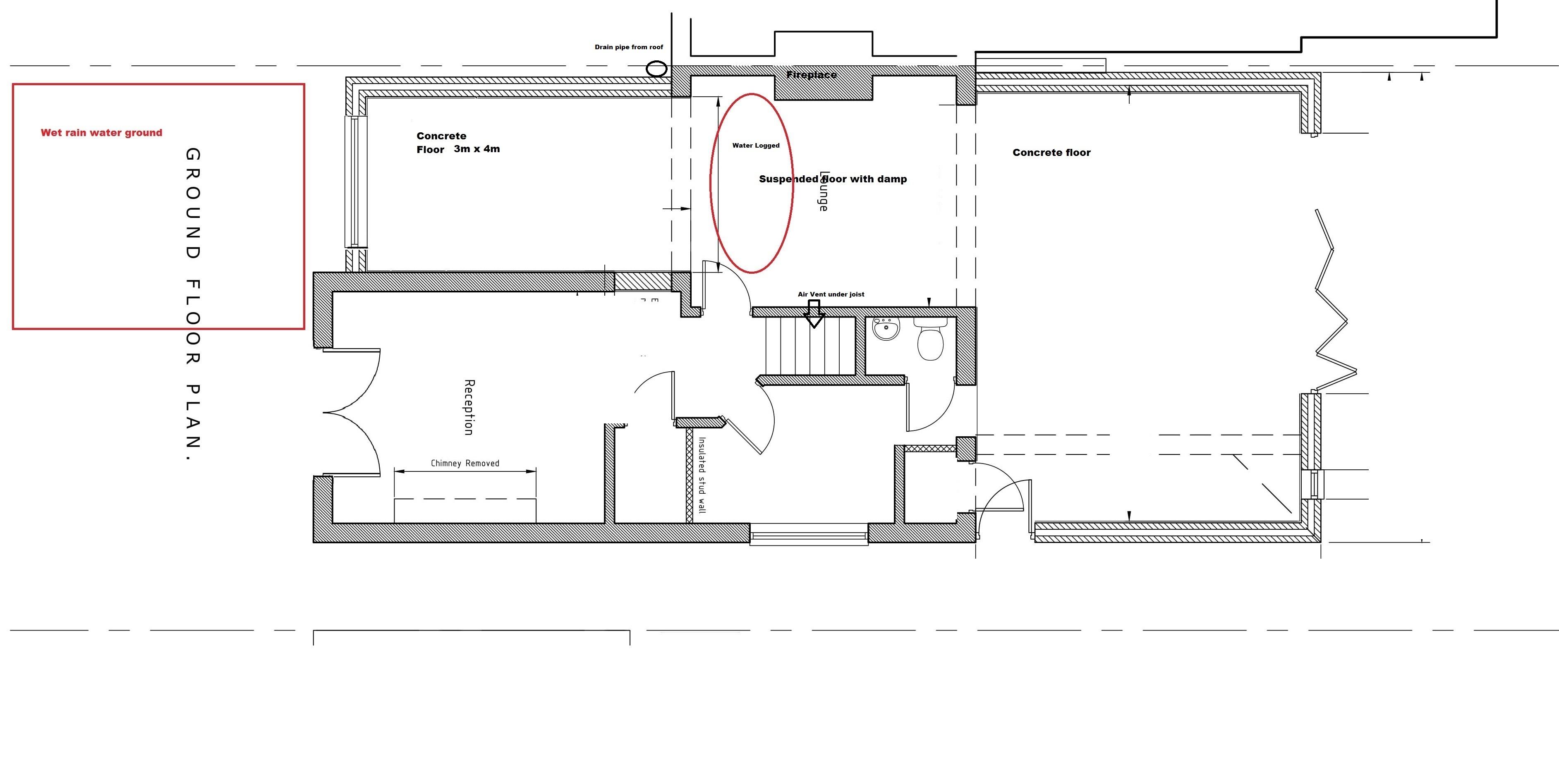

A Best Practice Approach To Insulating Suspended Timber Floors Fintan from our Technical Team discusses the thermal loss issues associated with suspended timber floors and outlines a best practice approach to tackling them At the turn of the 18th century, when construction techniques moved from boarded floors installed directly on the groundThe constructional details from the bottom of the foundation to 400mm above finished floor level and include the abutment of both floors (For the purposes of this drawing, show a minimum 15 metres width for each floor type) (b) Indicate on the drawing a design detail to show the cross ventilation of the suspended timber floorE7 Intermediate floor between dwelling;

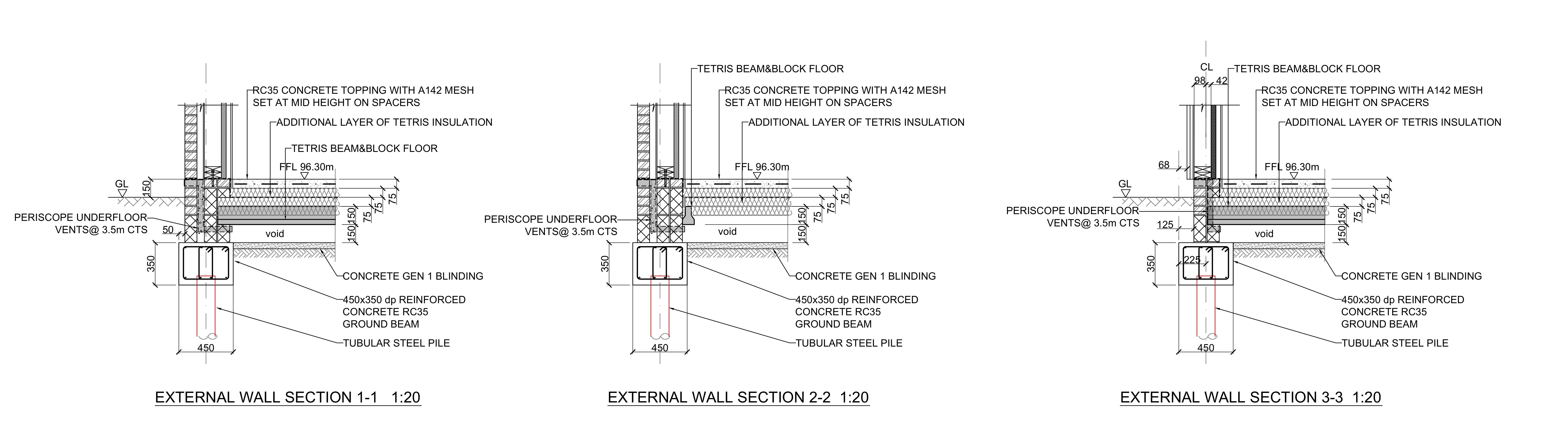

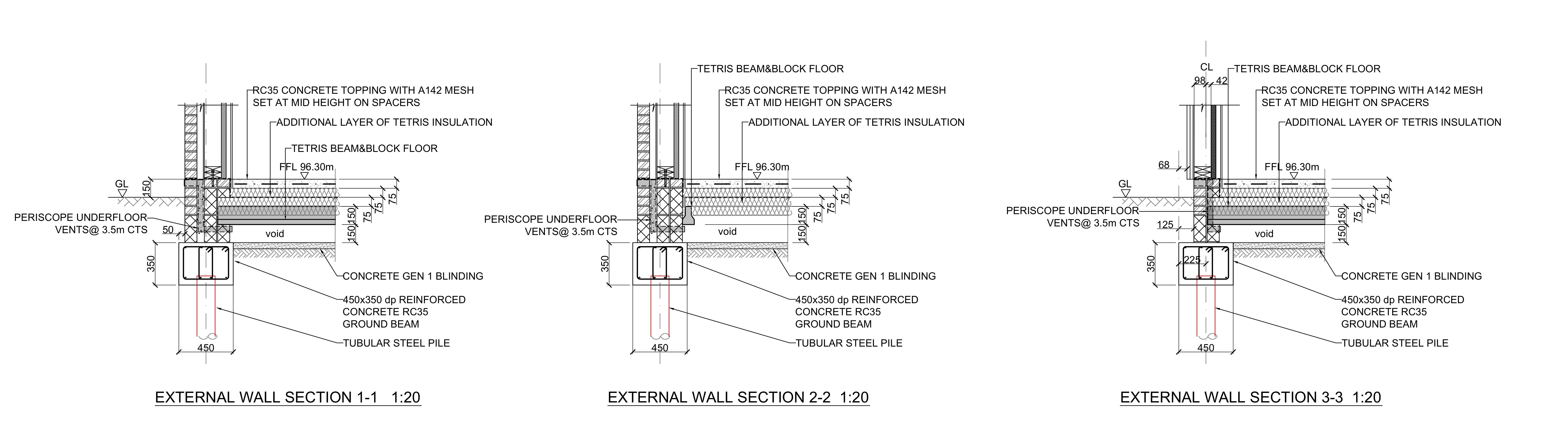

Critique My Foundation Detail Please Foundations Buildhub Org Uk

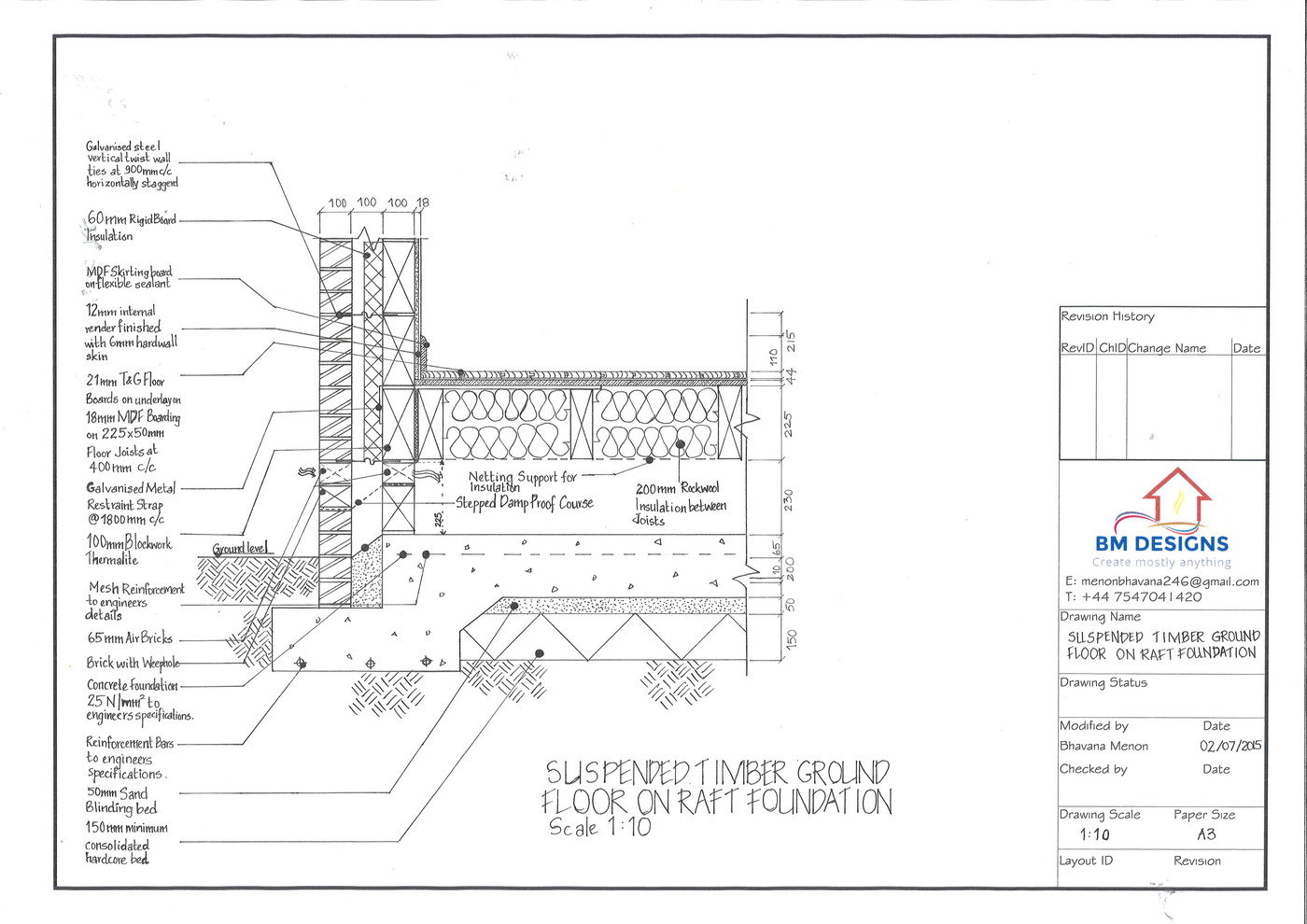

Ground suspended timber floor detail drawing

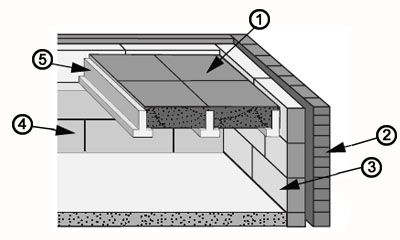

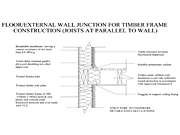

Ground suspended timber floor detail drawing-Junction between solid floor and timber framed wall FloorExternal Wall Junction for Timber Frame Construction (Joists at parralel to wall) FloorExternal Wall Junction for Timber Frame Construction (Joists at right angles to wall) Solid Ground Floor (65mm Concrete Sand Cement with light reinforcement) Solid Ground Floor (65mm concrete sand 2 Solid ground floor 3 Suspended timber floor 4 Suspended concrete floor 5 Ribbed floor 6 Hollow pot floor 7 Raised floor 8 Plenum 9 Floating floor 10 Sprung floor

Concrete Vs Timber Floors

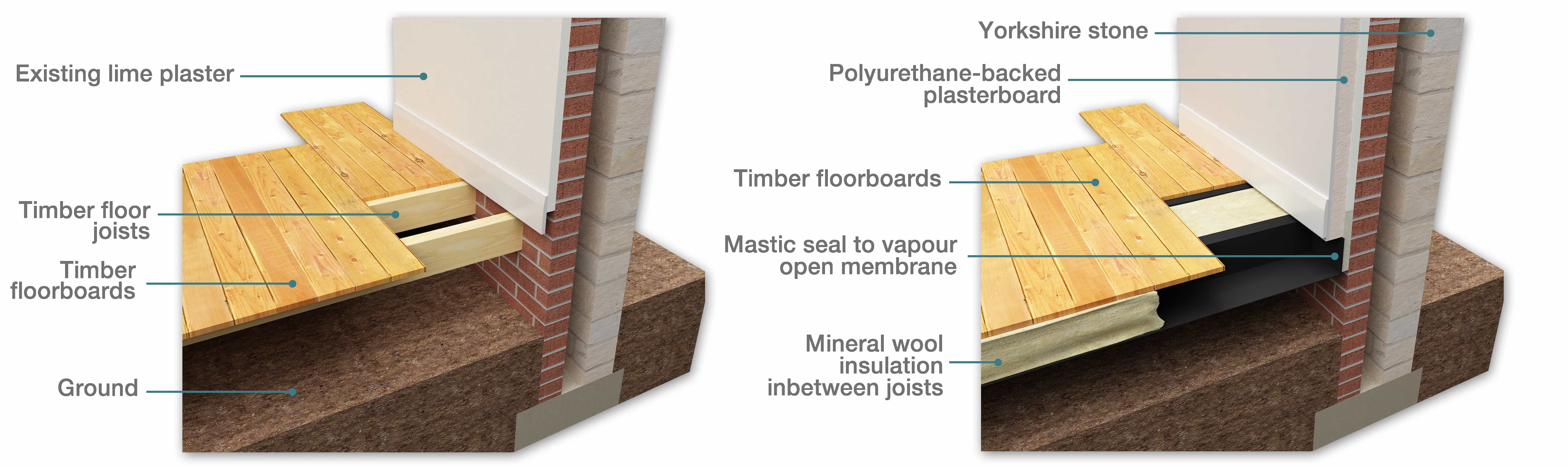

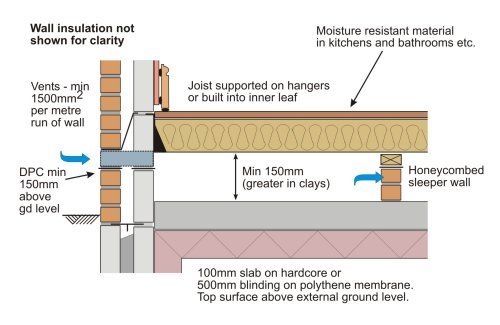

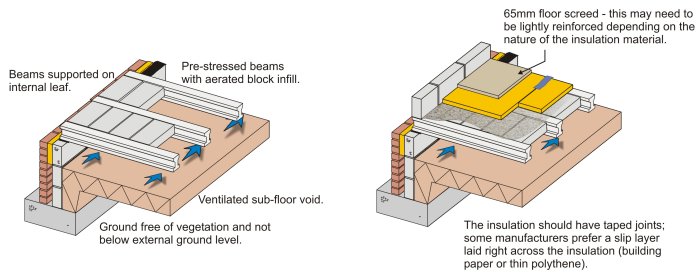

Ground Floor – Hollow or Timber Floor Hollow floors, also known as suspended or timber floors, are simply timber joists suspended across and supported by load bearing walls under the floor The ends of these timber joists are built into, or suspended by joistNHBC requires ground floors to be constructed as suspended floors in the following situations where the depth of fill exceeds 600mm, as described in Chapter 51 'Substructure and ground bearing floors' (Design) where soil swelling may occur, as described in Chapter 42 'Building near trees' on sites which have been subject to vibratory groundE Exposed floor (normal) P1 Ground floor

Suspended timber ground floor Guidance Diagram 12 Typical section through a suspended timber ground floor Plan detail of timber stud separating wall as Wall type 41 (new buildings) of The design, workmanship and selection of materials for flat roofs Cavity closersYou are CAD Drawings HY – Sectional Detail HY02 Window – head detail HY03 Window – Sill details HY04 Window – Jamb detail HY05 Wall – Ground floor detail HY06 Wall – intermediate Floor detail HY07 Wall – Separating floor detailThis Guide describes and illustrates the various types of concrete slabonground floor systems and suspended floors suitable for residential buildings ranging from single, detached houses to medium density buildings of apartments and flats

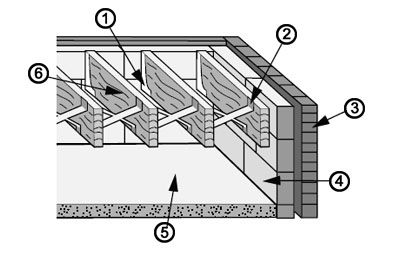

1 Suspended Timber Floor Construction There are several different types of suspended timber ground floor construction These vary depending upon the age of the building, its structural form, limitations of the timber available and the local traditions The ground floors in most medieval domestic buildings were simply compacted earth By the#09 • Timber Flooring Design Guide Page 6 1 Timber Flooring and Floor Finishes 11 Movement in Timber Floors Prior to discussing timber flooring products, it is important to understand the relationship between timber, humidity in the air surrounding it and the dimensional changes that occur as the result of changes in humiditySingle joist timber floors 2 c Joist Span (below 3m) Strutting a b PLAN Detail at c' Air space Floor boards Joist Wall Wall plate Ceiling Section on ab Joist Wedges Floor boards 300 – 400 mm Herring bone strutting Double joist timber floors 3 18m to 24m 36 to 75m 300mm Binders Bridging joist @ 300 mm c/c PLAN Methods of fixing binders

The Different Types Of Suspended Wooden Flooring Construction

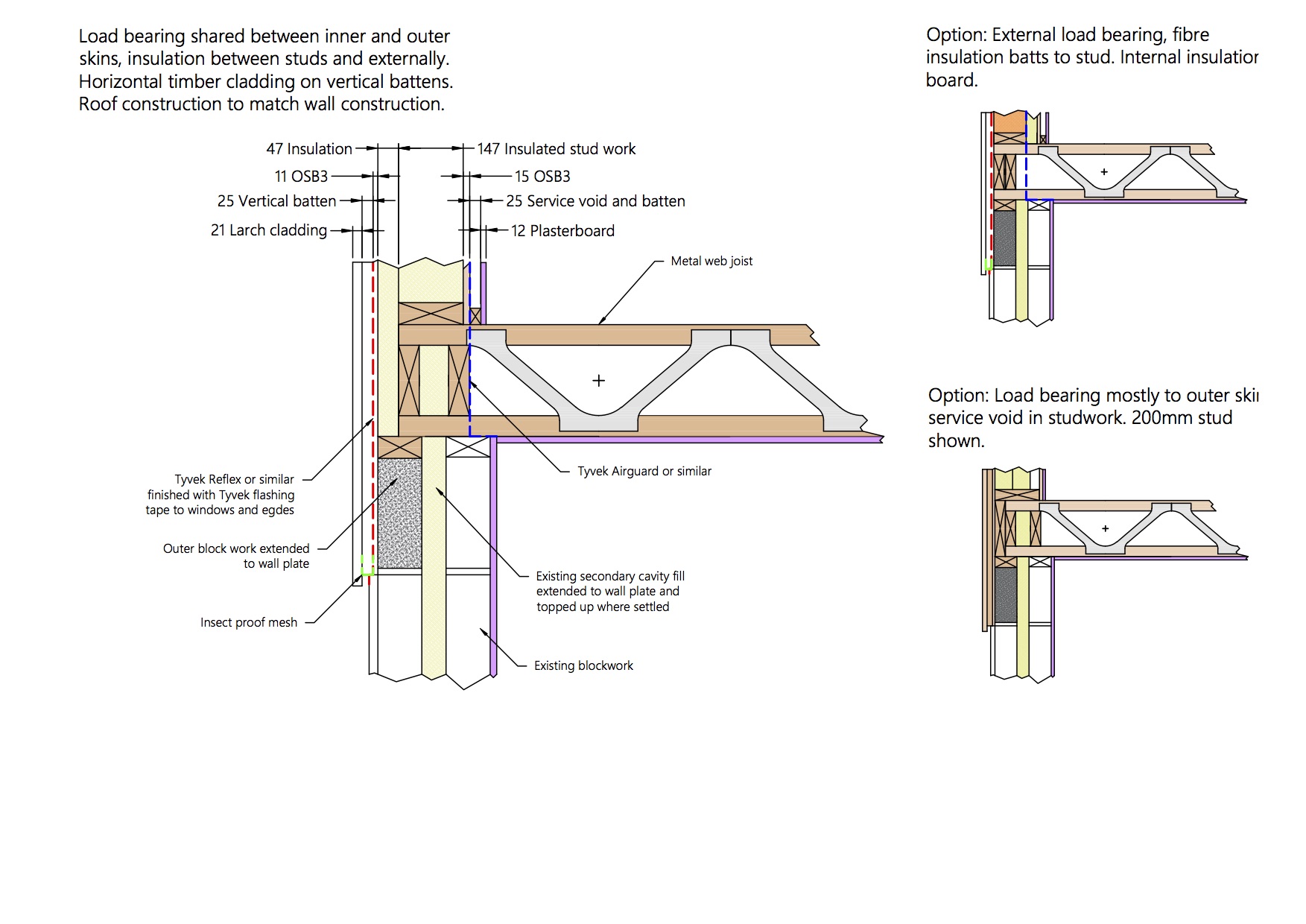

Technical Building Foundation Construction Drawings Cavity Wall

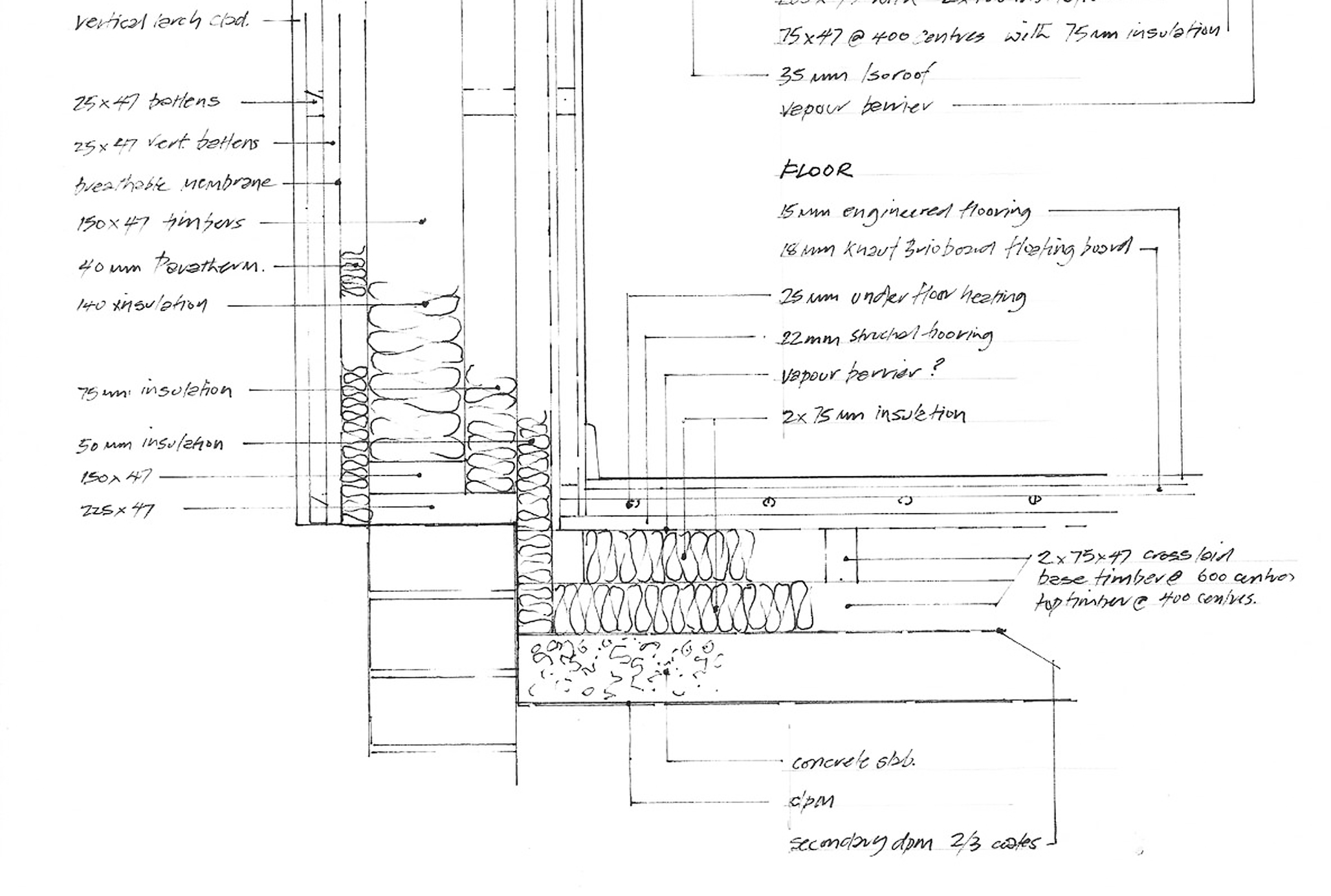

Proposed Upper Ground Floor Timber Floor Typical BuildUp Location UGF Typical Floor Buildup Details E/CON002 15 @ A1 JK B 005m01m 02m 03m 04m 05m TENDER DATE GENERAL NOTES THIS DRAWING IS TO BE READ IN CONJUNCTION WITH ALL OTHER OSEL TENDER/CONSTRUCTION DRAWINGS THIS DRAWING IS PRODUCEDSuspended Timber Floor Specific applications Specific applications Stockists ;TIMBER FRAME STANDARD DETAILS SEPTEMBER 09 Building 1 Grosvenor Court, Hipley Street 41 Ground Floor 42 Intermediate floor – Joist parallel 43 Timber Frame Design and Structural Engineers Silvatec Levels Ltd Suppliers of Panel Plumb

Www Rbkc Gov Uk Idoxwam Doc Drawing Pdf Extension Pdf Id Location Volume2 Contenttype Application Pdf Pagecount 1

Cdn Mitekea Com Wp Content Uploads Sites 3 18 10 Wopt Issue 7 Pdf

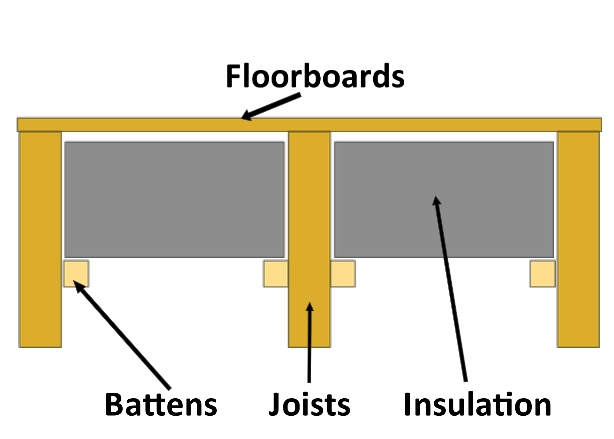

Timber Suspended Ground Floor DETAIL 403, 11 Timber Suspended Ground Floor If installing compressible insulation, ensure full insulation depth between joists Ensure insulation is in contact with underside of timber flooring Seal all penetrations through air barrier using a flexible sealant or tape Seal between wall and floor airTimber Frame Junction Details 312 Timber Frame – Timber suspended ground floor whether both design proposals and work on site will deliver the intended levels of performance Use of cited psi values The psi values cited for each example detail may be used in calculation ofA selection of floor detail drawings including block and beam floors, timber suspended floors, solid ground floors and upgrade floor details Drawings are directly downloadable in Jpeg (1600 by 10px), DXF and DWG (cad) formats Note The Detail Drawings are applicable to work in England & Wales only

6 4 14 Timber Joist And Restraint Strap Nhbc Standards 21 Nhbc Standards 21

Suspended Wooden Floor Cad Details Cadblocksfree Cad Blocks Free

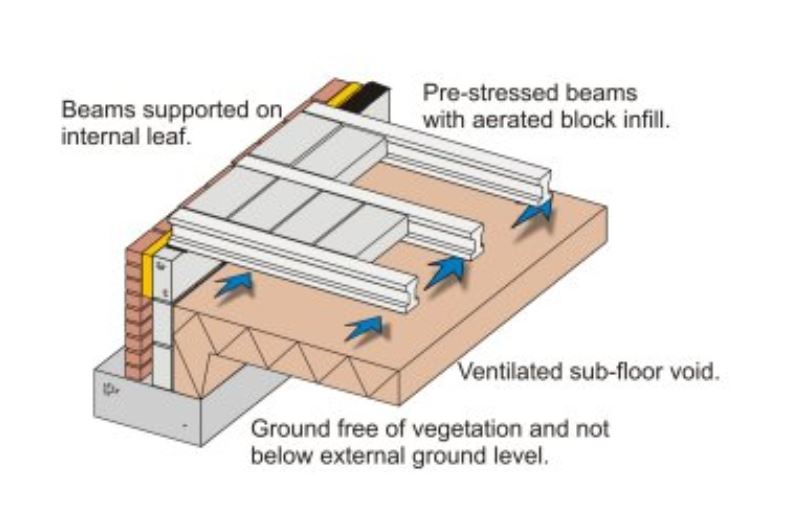

5of 8 Introduction April 13 ®Update robust details Key for Tables 3b and 3c Permissible wall and floor combinations for flats/apartments requiring no precompletion sound testing F Only the separating floor requires precompletion sound testing W Only the separating wall requires precompletion sound testing 1 Lightweight steel and timber frame walls may be constructed above A suspended floor is a ground floor with a void underneath the structure The floor can be formed in various ways, using timber joists, precast concrete panels, block and beam system or cast insitu with reinforced concrete However, the floor structure is supported by external and internal wallsGovernment Accredited Details Developed by BRE for local government Search Number of results 23 412 Timber suspended floor Wallground floor junction Scottish Building Standards Steel frame 017 013 E5 0077 0 416 Ground floor (timber) / separating wall

11 E T Tech Drawings Ideas Floor Insulation Timber Home Insulation

Conservatories Online Suspended Floor Detail

Ground bearing slabs should not be used in ground conditions where heave can occur or where the foundation depth is greater than 15m Under these circumstances a suspended floor construction should be used Site preparation The ground beneath the floor should be stripped of all topsoil, organic matter or tree roots prior to filling and compactionSuspended timber floor As a requirement of the Building Regulations the structure should be protected against the growth of weeds and other plantlife The ground should have a layer of concrete poured across and there should be a ventilated gap of at least 150mm between the underside of the timbers and the concrete, to prevent moistureA – Standard Designs Transmission Typical Details for Optical Ground Wire Splice Structures 114 41 6157 – Standard Design Transmission Lines Type 3TD 115Kv 3pole Tension Dead End Structure 115 41 9002 Rev N – Transmission Line Standards Barbed Wire Gate For Right ofWay Fences

Suspended Floors All You Need To Know Thermohouse

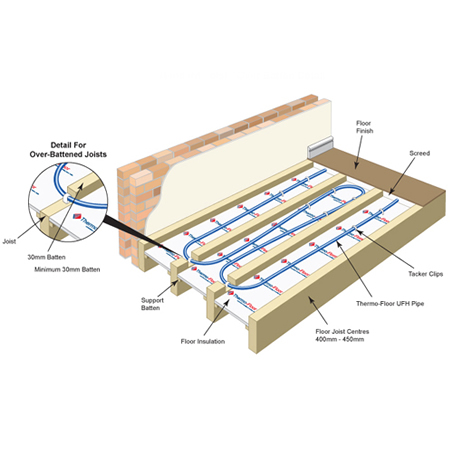

Underfloor Heating Suspended Flooring

The timber floor structure will be shown in detail on the plans and drawings These must be drawn according to SANS 100 which specifies how timber buildings should be built and there should be at least 450 mm between the joists and the ground Upperfloor suspended timber floors are built in a similar way although the floor joists may beE10 Eaves (insulation at ceiling level) E11 Eaves (insulation at rafter level) E12 Gable (insulation at ceiling level) E16 Corner (normal) E17 Corner (inverted) P4 P5 Roof;To get the timber suspended floor to act as a screeded floor and to give out more heat, the air gap between the insulation and the floor boards should be filled with a lightweight screed mix The infill is normally 101 sand/cement mix at a height of 25 mm

Step By Step Suspended Timber Floors Green Building Store

Underfloor Heating For Joisted Timber Floors Warmafloor Esi Building Services

Timber deck finish can also be used – if this is specified a vapour control layer must be included in the design under the timber deck A void is left under the floor of at least 150mm between the soil and underside of the beam If heavy clay soil is present it is good practice to increase the void depth to as much as 225mm or possibly moreGround floor beam details (a) str/17 december, 17 str/31 december, 17 str/32 december, 17 str/33 december, 17 third floor beam layout plan str/34 december, 17 any variations or substitutions of materials or details from those indicated on the drawings may only be made with prior approval of the engineer b foundationThis chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 Contaminants

Internal Partition To Suspended Floor Detail Drawing

Techmanual December 13 Website By Jamesjones Sons Issuu

E6 Intermediate floor within a dwelling;For slabonground floors it provides an understanding of the footing/slab selection, design, detailing and construction requirements contained in AS 2870 and the Housing Provisions of the BCA The requirements of AS are also covered For suspended floors it covers both upper floors and those at ground level where a slabonground mayWhile the details in this Technical Note address serviceability concerns associated with glulam connection detailing, it is important to emphasize that all connection details must effectively transfer the design loads imposed on the structure and that all designs be in accordance with accepted engineering practice

Architectural Designs And Drawings

Floors

Structural support, in suspended floors the system has a support structure that carries and transfers the load to the footings The structural support for suspended slabs for the ground floor is usually dwarf masonry walls For timber floors the substructure generally consists of joists, bearers and engagedDifferent types of ground floor suspended flooring Suspended timber floors need to have spaces underneath ventilated via air 'bricks' through the outer walls and gaps in any internal walls so that the air can move across the building underneath the floors to prevent the build up of moisture in the timber which could lead to fungal attackConstruction Studies drawing detail of suspended timber floor

Suspended Timber Ground Floor Insulated Between Timber Joists Quinn Building Products Timber Flooring Timber Floor Insulation

Floor Detail Drawings

SELECTING YOUR ROBUST DETAIL Houses will only need to be registered for Separating Walls The robustdetails® scheme does not apply to internal floors in houses When using Robust Details walls and floors in flats, details from the same construction group should be selected Refer to the relevant Combination Table to ensure compatibilityGRoUnD FLooR ConstRUCtIon 4 GRoUnD FLooR ConstRUCtIon oVeRVIeW This text introduces a variety of subject matter related to Building and Construction, at a trade level It outlines both traditional and alternate suspended timber flooring systems as well as upper floor construction methods for two storey workFor most situations where internal floor areas are greater than 600mm below external ground level, additional protection may be required Therefore, these drawings are for general guidance only, and further advice should be sought when necessary from our Technical team Phone 9440 or Email technical@riwcouk

Step By Step Suspended Timber Floors Green Building Store

Wooden Floor New Suspended Wooden Floor Construction

6410 Construction of timber floors Upper floors shall be constructed in a workmanlike manner and provide satisfactory performance Issues to be taken into account include levelling joist spacing and clearance support There are approximately 10 million suspended timber ground floor constructions in the UK and millions more globally However, it is unknown how many of these floors Why Use Suspended Timber Floor A suspended timber floor is the chosen way for many builders and consumers because of the following facts It has simply the best construction way for sloping sites, lowlying areas or sites with bad climatically conditions It is more cost effective in residential areas

Detail Post Floor Details First In Architecture

Floor Detail Drawings

Build 139 Build 151 —— December 13/January 14 — December 15/January 16 — 31 DESIGN Suspended floors RIGHT COMMON QUESTIONS ABOUT DESIGNING AND BUILDING SUSPENDED FLOORS USING NZS The BRANZ Technical Helpline often receives queries for designing and building suspended timber floors and dealing with upliftAdditional Construction Details Drawings As well as the small selection of foundation, wall, floor and roof construction detail drawings shown here, many of the Building Notes have a related Construction Detail Drawing, with specific dimensions eg rafter sizes, spans, insulations types, for purchase with the Building SpecificationsThe timber floor deck Timber Suspended Ground Floor T , Timber Suspended Ground Floor Seal all penetrations through air barrier using a flexible sealant Seal gap between skirting board and floor with a flexible sealant Provide similar air seals at all internal partitions Seal joints in timber floor with suitable glue Fully support and fix any

Introduction To Beam And Block Floors Construction Detailing And Selection

Concrete Vs Timber Floors

Characteristics Ecological Timber Floors are ecologically friendly Since it is a natural resource, timber is both renewable and recyclable Easy to maintain Maintenance of timber floors is easy Flexible Hardwood timber floors will always look good both in contemporary and traditional interior design 46 47 47 48Suspended Wood Floor Application 21 SlabOnGrade Application 25 Joist Space Application 30 software or a pipe layout drawing can provide these details RFH WarmSource REHAU's design software is a radiant floor heating system ground between their arms, or the use of an uncoiling device such as the RAUPEX Uncoiler 9

Critique My Foundation Detail Please Foundations Buildhub Org Uk

Www Woodspec Ie Docs Woodspec final section b Pdf

The Different Types Of Suspended Wooden Flooring Construction

1

How To Choose A Floor Structure Homebuilding

Floor Detail Drawings

What Is A Suspended Timber Floor Discount Flooring Depot Blog

Building Construction Paper 2 Nov Dec 11

Suspended Floors All You Need To Know Thermohouse

Internal Partition To Suspended Floor Detail Drawing

Floors And Flooring Sans Building Regulations South Africa

Suspended Timber Floor Detail Youtube

Www Scoilnet Ie Uploads Resources 248 Pdf

Thermoblock A Simple Solution To Thermal Bridging From Marmox

Constructing A Suspended Floor To Building Regs Youtube

Detail Post Floor Details First In Architecture

Eurima Suspended Timber Floors

Floor Detail Drawings

Suspended Timber Floor Construction Studies Q1

Suspended Floors All You Need To Know Thermohouse

Suspended Floors All You Need To Know Thermohouse

Q Tbn And9gcttjz3x5dph2qk Zk1wzuibsguzgtcn 4sdf1uyusei Yzqqnd9 Usqp Cau

Floor Detail Drawings

Figure B 10 Figure B 10 Alternative Floor Slab Detail The Suspended Reinforced Concrete Garage Workshop Plans Workshop Plans Concrete

Floor Detail Drawings

Diy Floor Insulation Thegreenage

Detail Post Floor Details First In Architecture

Detail Post Floor Details First In Architecture

1

Diagram Of Suspended Timber Floor With Underfloor Heating Pipes Underfloor Heating Floor Heating Systems Hydronic Radiant Floor Heating

Puddles Of Water Under Suspended Floor Damp Dpcs Buildhub Org Uk

The Different Types Of Suspended Wooden Flooring Construction

Floors And Ceilings

1

Concrete Vs Timber Floors

Installing Ufh Within A Suspended Timber Floor Ambiente

Building Guidelines Suspended Timber Floors

Ground Floors Youtube

Suspended Timber Floor Detail Youtube

Suspended Timber Floor Construction Timber Flooring Roof Construction Timber

Timber Flooring Flat Roof Extension Floor Insulation

Suspended Floors All You Need To Know Thermohouse

Www Diynot Com Diy Attachments Suspended Timber Floor Pdf

Pin By Seb Neal On Architectural Technology Self Build Houses Timber Frame Timber Cladding

Www Scoilnet Ie Uploads Resources 248 Pdf

How To Choose A Floor Structure Homebuilding

Suspended Timber Floor And How To Build A Floating Hollow Timber Floor Diy Doctor

6 Ground Floors Construction Studies

Underfloor Heating System Floor Constructions And Height Build Up Details Chelmer Heating

Floor Framing Structure

Conservatories Online Suspended Timber Floor Detail

Building A Timber Frame First Floor Over A Cavity Wall Timber Frame Buildhub Org Uk

Suspended Timber Floor Construction Studies Q1

Solid Ground Floor Wikipedia

Suspended Floors All You Need To Know Thermohouse

Fbe 03 Building Construction Science Lecture 3 Floor

Radon Gas Barriers In Timber Frame Buildings Installation Tips

Suspended Timber Floor Detailed Drawing Youtube

Http Foresitebuildingcontrol Co Uk Pdfview Aspx Filename F 7 4c

Detail Post Floor Details First In Architecture

Suspended Ground Floors Suspended Timber Floor 800x400 Png Download Pngkit

Evolution Of Building Elements

Floor Detail Drawings

Suspended Floors All You Need To Know Thermohouse

Timber Frame 1st Floor Detail Youtube

Pin On Ae

Suspended Timber Floor Construction Studies Q1

Ground Floor Build Up Alternative Timber Frame Buildhub Org Uk

Suspended Timber Floor By Bpptech Issuu

Learning Outcome Lesson Objective Ppt Video Online Download

Free Cad Blocks Floor Details

Technical Detailing By Bhavana Menon At Coroflot Com

Detail Post Floor Details First In Architecture

Top Schematic Drawing Of The Detailing Between Masonry Ground Floor Download Scientific Diagram

Part 1 Technology 3 Folio

What Is A Suspended Timber Floor Discount Flooring Depot Blog

Building Guidelines Suspended Timber Floors

Concrete Slab Ground Floor Insulation With Walltite

Floor Detail Drawings

Floors And Ceilings

0 件のコメント:

コメントを投稿